Handloom: A Tool of Women Empowerment – But Assam’s Muga Silk Industry Has An Entirely Different Story To Tell…

This year, during the festival of Onam, columnist Shefali Vaidya had posted in Twitter a beautiful picture of herself wearing a traditional golden-ivory mekhela saador from Assam teamed with a red blouse and matching jewellery. Her tweet spoke a lot about the immense diversity of Bharatvarsha from the North to the South and the West to the East in terms of people’s dressing styles, food habits and much more. In the photo, she had compared the colour of her mekhela saador with the colours of the Kasavu saree from Kerala.

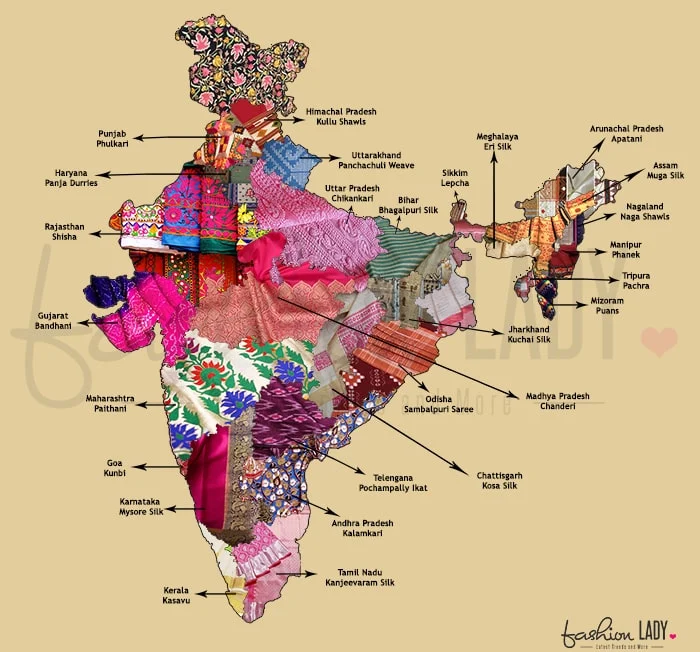

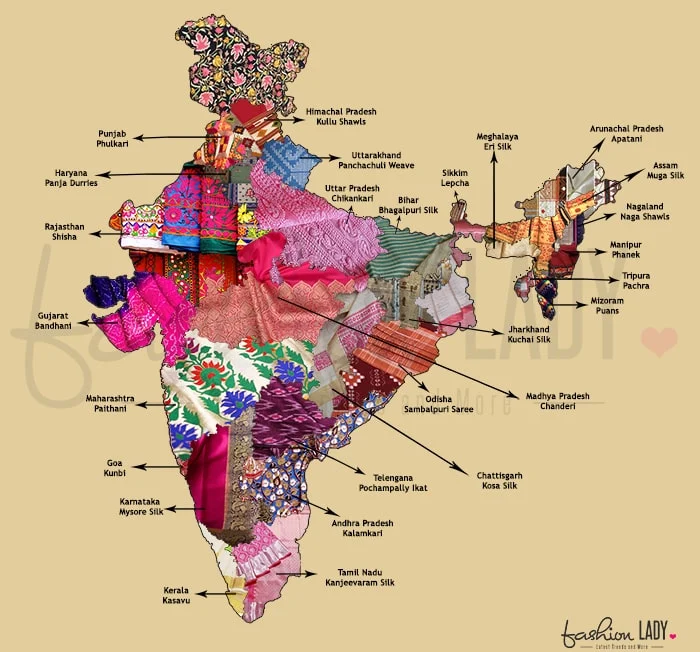

For those who might not know, mekhela saador is the traditional dress of women in the state of Assam. The most famous and royal-looking ones are those which are made of the enviably distinctive golden-yellow muga silk, which has also obtained the Geographical Indication (GI) rights from the GI Registry of the country. The cultivation of muga is endemic to the state of Assam since time immemorial. It is an exotic variety of silk that is manufactured from the cocoon of a silkworm called Antheraea Assamensis found only in the Brahmaputra Valley.

Muga occupies a unique position in the Assamese cultural sensibilities so much so that without it, the very identity and existence of its people would remain incomplete. The Muga Silk GI Logo has been authorised for use by the Assam Science and Technology and Environment Council (ASTEC) – the proprietor of the GI Registration – with a view to counter the threat posed by unscrupulous traders to this famed golden silk that is unique to Assam. The cost of one pure muga mekhela-saador may even go up to Rs. 55,000-60,000 in the market! It is a silk well-known for its high resilience and durability.

Recently, e-commerce marketplace Flipkart had inked an agreement with the Government of Assam to promote the state’s local artefacts and handloom products on its web-portal. This has been done in line with the PM’s call for ‘Make in India’ and support for domestic manufacturing. It shall be executed under Flipkart’s Samarth Program, which has already been promoting Indian handicraft and handloom products since a long time now, besides supporting the livelihood of more than 6,00,000 artisans, weavers and micro-enterprises across India.

The move is expected to help Assam’s local artisans and handloom weavers, especially women, showcase their hallmark products to millions of customers across the country. As per the 3rd Handloom Census (2009-10), there are about 43.31 lakh handloom weavers and allied workers across the country, of which 77% are women weavers who are involved in weaving and other allied activities. But, the question remains – Will this initiative of Flipkart help the state’s poor muga farmers reap the benefits of local economic development? Or is it still going to be a one-sided affair of profit-making in which the Bhagalpur tassar silk industry of Bhagalpur, Bihar has been deriving the maximum benefits uptil now?

Bhagalpuri Silk is a unique brand in the huge Indian saree industry, and its popularity can be gauged from the fact that it occupies an esteemed place for itself in numerous emporiums across the country and online shopping sites, catching the attention and appreciation of the buyers worldwide. Apart from the tassar silk which is the most common form of Bhagalpuri silk, the industry has been manufacturing and marketing another product, i.e. muga, which has become immensely popular in the last one and a half-decade. It is a much-accepted and well-known fact that the illegal sale of muga cocoon waste from the Lakhimpur-Dhemaji belt of Upper Assam has played a vital role in the success of the silk industry of Bhagalpur, Bihar.

The muga cocoon is reeled into threads after which it is woven into beautiful pieces of clothes with unique Assamese designs, patterns and artwork as finished products to be sold in the market. It is the process of reeling from muga cocoon which, in fact, is the most crucial part of the entire business of muga cultivation. It involves meticulous efforts and concentrated skill and is done entirely by local village women who have learnt the art from previous generations of women in the same village. They have been conserving this traditional culture and the respective bio-resources associated with it through interlinking it with their annual crop cycle – a perfect example of sustainable agriculture.

In fact, the muga culture, or the rearing and manufacture of muga silk, has been a traditional practice among the people of Assam, especially concentrated in the districts of Lakhimpur and Dhemaji. The Dhakuakhana sub-division of Lakhimpur district has been a major muga-growing area of the world. There are around 1 lakh traditional muga farmers in Dhakuakhana growing som (Persea bombycina kost), the host plant, in an area of about 1,602 hectares of land averaging 0.15 hectare of holding of som plantation per family. Women have always played an indispensable role in this industry, for they provide at least 50% of the contribution through direct participation in the entire activity. At current market prices, muga silk that is reared in one hectare plantation can generate a total product value of Rs. 10 lakh (approximately 15,000 US dollars) in a year.

While reeling the golden-yellowish thread from the muga cocoon, the women also keep aside the wastes that come out of the process. Muga waste is locally known as peloniya muga, i.e. the last layer of delicate thread which is left behind inside the silkworm’s cocoon. It is being taken by women themselves in their fingers from the traditional reeling tool called bhaori kata, after which they leave them wrapped on a small bamboo pole. Generally, these wastes from the muga cocoons are of very little or almost no use, and are thus collected by scrap dealers from door-to-door in this region of Upper Assam, but at a very low price. The rearers too, cannot demand more since they are of no use to them. For long, this waste has been peddled outside its native state to make imitations, often mixed with other cheap materials. Ironically, these same imitations make their way back home and are being sold to the people here in posh handicraft exhibitions and handloom fairs.

In the opinion of Jitul Saikia, a national award-winning agriculturist and eminent muga researcher from Batomari village near Ghilamora in Dhakuakhana sub-division, the muga cocoon wastes are being bought by the scrap collectors at Rs.100-150 per kilogram from the locals and then they are sent to Bhagalpur – the centre of the famous Bhagalpuri silk sarees, dupattas and cut-pieces. Once it so happened that the cocoon bank of the Assam Sericulture Department bought 105 quintals of muga cocoon waste at Rs. 500 per kilogram from the scrap collectors in 2017 to be converted into ‘Ghisa Muga Silk’ that is produced in Sualkuchi, the commercial silk-hub and weaving centre of Assam. As reported by Saikia who himself runs an NGO called Wild Silk North-East, after 2017, the Assam Sericulture Department has not procured muga wastes from the Dhakuakhana-Dhemaji region for its cocoon bank, thereby enabling the scrap collectors to supply the wastes directly to Bhagalpur at higher prices.

This illegal trade of collecting and supplying of the muga cocoon wastes from the muga endemic zone of Dhakuakhana-Dhemaji in Upper Assam to Bhagalpur in Bihar has been continuing since a very long time, thereby depriving the local economy from a rich source of revenue that it genuinely deserves. This region produces almost 10 crore muga cocoons annually. These cocoons reel 20,000 kg of muga silk threads, each kg making 15 metres of a sheet of cloth, approximately earning Rs. 72 crore in total. In Bhagalpur, the muga cocoon waste or peloniya muga is refined into ‘pure’ muga silk and then turned into eye-catchingly attractive, fashionable and very expensive clothes.

Unfortunately, it is a sad story of the transformation of a household waste from a traditional reeling practice dominated by women in rural Lakhimpur into an exotic brand worldwide that is promoted by some high-end fashion designers and international brands. Unfortunately, the rural Assamese women weavers engaged in the production of muga silk are unaware of this reality. Notably, the Bhagalpuri silk industry is reaping huge profits and earning an extravagant brand image for itself from the muga cocoon wastes that are collected unethically from the original rearers and producers of muga silk in rural Assam. In the words of Jitul Saikia himself, “The Bhagalpuri muga silk is actually the muga silk of Dhakuakhana-Dhemaji.”

Traditionally, the muga cocoon wastes were reeled to make clothes for various purposes in Assam. Till almost two decades ago, these were turned into a piece of thread called Jothori Muga that was weaved to make warm clothes for the winter season. Women used to make bor-kapur (large sheets of cloth) from the muga cocoon wastes to be used with multiple folds in the bed for warmth during the winters. Waistcoats and vests were also made from it for they were far warmer than endi/eri silk. However, the lack of interest displayed by today’s young generation in making clothes from this valuable waste product, its sale to scrap collectors and also the lack of awareness on the immense potential of the waste, have been taken undue advantage of by middle-men and brokers. All these factors have eventually benefitted the Bhagalpuri silk industry while depriving the original manufacturers of their legitimate due.

The muga silkworm plays an important role in environmental protection in this part of the world by means of agro-forestry conservation and sustainable use of muga seri-biodiversity. Moreover, all the host plants of the muga silkworm are evergreen and can be used for the maintenance of environmental sustainability such as soil protection. The pupae of the silkworm could also be utilised as fertilisers, fish feed or in any other animal feed industry. On top of all these, the muga waste has a potential of revenue generation of upto Rs. 23 crore and direct employment for around 5,000 people engaged in the activity. Out of the 40,000 kg of muga waste generated annually, 25% can be repurposed as thread that amounts to 10,000 kgs of yarn and fabric both; and, the turnaround for the same totals at roughly Rs. 23 crore. It’s high time that Assam’s muga silk is bestowed with the due credit it rightly deserves!

References:

DISCLAIMER: The author is solely responsible for the views expressed in this article. The author carries the responsibility for citing and/or licensing of images utilized within the text.